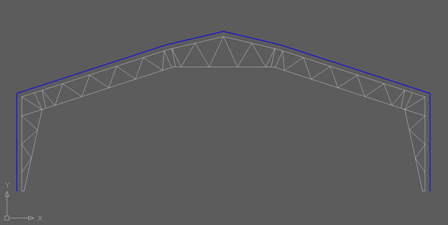

Mobile steel framed hangars covered by PVC are one of the leading alternatives to traditional steel covered buildings. Design, calculations and manufacture meet DIN 18800 and ISO 9001 quality standards. Width of the hall can be up to 80 m without the use of supporting columns. If necessary, additional heating can be installed so that warmth-keeping characteristics would be the same as ones of traditional buildings. Ventilation and lightning can be designed and installed additionally as well.

Wind and snow loads are calculated according to EC3,

standard prefabricated halls are calculated for 1.8 kN/m2 of snow and 32 m/s of wind loads, safety factor 1.5.

Frame construction is produced from structural steel, the surface of which is soundblasted (ISO 8501-1:1988 Sa-2,5) and covered with epoxy paint (120 µ) of RAL 7000 color.

Section pitch for standard production is 3 m.

All frame elements are designed so that they can be easily mounted and dismounted. Maximal construction element length doesn’t exceed 13 m.

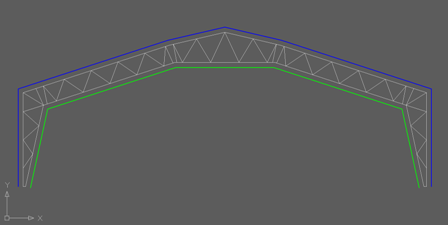

Cover

Cover is made from light translucent, flame retardant (DIN4102B1/M2 standard) PVC material. It’s both sides are covered by acrylic layer. PVC material is delivered in rolls, which are welded by the use of RF current into one piece of cover, which makes it absolutely hermetical. PVC material elasticity gives an opportunity to avoid foundation; it also gives a possibility to assemble hangars on uneven places; and it does not react with chemicals after storing.

There is no need to use artificial lightning in a daytime because roof cover is produced from light translucent (10-17%) material.

PVC cover life duration

One of the most suitable world materials for the manufacture of big constructions is the material of a French manufacturer “Ferrari”. Because of the technologies used by the manufacturer, this material has the best stretching characteristics; that’s why it serves and keeps aesthetic appearance longer than materials of other manufacturers. Long life duration of PVC material was approved in 2000 by a test on the hangar of 58 m width and 250 m length. After 18 years of operating, the characteristics of the material haven’t almost changed:

• weight - 99 %

• one way stretching (warp) - 99 %

• another way stretching (weft) - 84 %

Currently, the service life of the construction is close to 30 years.

Basic hangar package:

- frames;

- PVC cover (1 layer);

- Sliding gates (quantity and dimensions depend on chosen hall model.

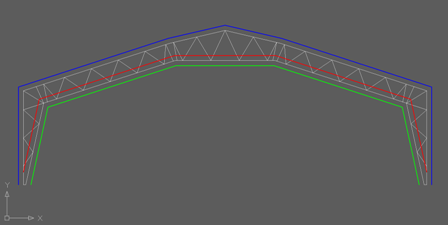

Additional insulation

Additional PVC layer is applied to the inner sides of the construction, which provides better thermal conduction factor, helps to avoid condensate problem, and improves acoustic characteristic and also aesthetic appearance of the hangar itself. Thermal conduction factor ~ 3 W/m2 K.

The higher < 1 W/m2 K coefficient can be reached installing a warmth-keeping jacket in-between two PVC material layers.

Hall walls can be covered by profiled steel sheets.

Colors

Roof is commonly produced from white light translucent material. Walls can be chosen by the customer.

Sliding gates (quantity and dimensions depend on chosen standard hall model)

Ground fixing

Base plates are fixed by metal anchors to the ground or screwed by nuts to the foundation.

Lifting equipment

Guarantee

Guarantee period is 3 years. All warranty rules and obligations are enclosed with our products.